DTKL-100FAutomatic Four-side sealing bag carton packing production line

summary

This packaging production line is applicable to the automatic box feeding packaging of small and medium-sized bags with loose, five viscosity particles and measurement requirements in medicine, food, daily chemical and other industries. Such as: granule, cereal, coffee, etc; Crystalline materials (monosodium glutamate, sugar, salt, etc.); Fine pellet materials (Chinese patent medicine, desiccant, etc.).

Characteristic

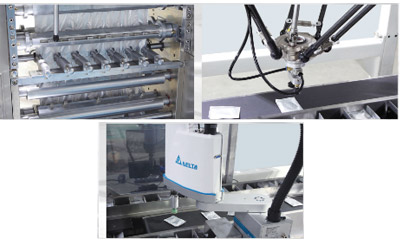

Use manipulator and visual inspection to orderly sort out various items or bags arranged irregularly; It has the characteristics of high speed, high precision, small space and high degree of automation.

■ the packaging forms of automatic feeding, box opening, box entering, batch number printing, box sealing and waste removal are adopted, with compact and reasonable structure and simple operation and adjustment

■ servo / stepping motor, touch screen and PC programmable control system are adopted. The man-machine interface display and operation are clearer and simpler, with a high degree of automation and more humanization;

■ the photoelectric eye automatic detection and tracking system is adopted, which can not leave the box empty, saving packaging materials;

■ large packaging range, convenient adjustment, and fast conversion between various specifications and sizes;

■ changing the specification does not need to change the mold, but only needs to be adjusted;

■ adopt automatic shutdown and overload protection device of main drive motor when articles are not in place in the box, which is more safe and reliable;

■ according to the requirements of customers, the upturned safety protective cover can be adopted, which is simple to operate and beautiful in appearance.

■ it can realize linkage production with vertical packaging machine, bag feeding packaging machine, horizontal packaging machine, three-dimensional packaging machine, labeling machine, inkjet printer, online weighing instrument, other production lines and other equipment

■ various automatic blanking devices and box feeding systems can be designed according to the requirements of packaging materials

■ hot melt adhesive machine can be selected according to customer requirements, which adopts hot melt adhesive spray sealing box and mechanical brush sealing box.

■ the packaging forms of automatic feeding, box opening, box entering, batch number printing, box sealing and waste removal are adopted, with compact and reasonable structure and simple operation and adjustment

■ servo / stepping motor, touch screen and PC programmable control system are adopted. The man-machine interface display and operation are clearer and simpler, with a high degree of automation and more humanization;

■ the photoelectric eye automatic detection and tracking system is adopted, which can not leave the box empty, saving packaging materials;

■ large packaging range, convenient adjustment, and fast conversion between various specifications and sizes;

■ changing the specification does not need to change the mold, but only needs to be adjusted;

■ adopt automatic shutdown and overload protection device of main drive motor when articles are not in place in the box, which is more safe and reliable;

■ according to the requirements of customers, the upturned safety protective cover can be adopted, which is simple to operate and beautiful in appearance.

■ it can realize linkage production with vertical packaging machine, bag feeding packaging machine, horizontal packaging machine, three-dimensional packaging machine, labeling machine, inkjet printer, online weighing instrument, other production lines and other equipment

■ various automatic blanking devices and box feeding systems can be designed according to the requirements of packaging materials

■ hot melt adhesive machine can be selected according to customer requirements, which adopts hot melt adhesive spray sealing box and mechanical brush sealing box.

Technical Parameter

| Item/ model |

DTKL-100F |

|

Packing speed |

30-100boxes/ minute |

|

Size range of carton |

L(75-160)mm×W(80-130)mm×H(15-60)mm |

|

Paper quality of carton |

250-300g/m2 |

|

Size range of use instructions |

L(100-180)mm×W(100-180)mm |

|

Paper quality of use instructions |

60-70g/m2 |

|

Packaging material |

Plastic/ aluminum, paper,/ plastic, plastic/ Plastic composite film |

|

Bag size |

L(55-160)mm×W(35-120)mm |

|

Volume per bag |

2-40ml(0.5-20g) |

|

Package material core diameter |

φ70-φ76mm |

| Maximum width of packing material | 900mm |

|

Cross-cut frequency |

60 beats/mn |

|

power type |

15KW |

|

Power supply type |

Three-phase four-wire380V50Hz |

|

Machine noise |

≤80dB |

|

Air supply |

0.5-0.7Mpa |

|

Air consumption |

160-200L/min |

|

Cartoning machine part |

L3100×W1200×H1900mm |

|

Multi-Column machine part |

L1500×W1540×H2200mm |

|

Mechanical hand arranging part |

L2500×W1500×H2200mm |

|

Machine weight |

4000Kg |

Sample

Detail drawing

358437202

358437202

18815157118

18815157118